你的产品或组件失败了吗?你需要了解原因? Learn from the past and prevent future failures with Element’s expert 故障分析服务. 找出根本原因, reduce risks, 提高产品的整体质量和性能, materials, 或组件,以防止未来的损坏.

什么是故障分析,为什么它很重要?

故障分析是多方面的, 全面的方法来理解为什么材料或产品失败. It is a critical aspect of product development and system improvement which not only helps you learn from the past but helps prevent future failures.

While the root cause analysis and associated impacts of any failure are the primary goals, the results can also help you make changes in your processes or material selection to prevent future occurrences. 阅读我们的文章找出答案 执行故障分析的三个原因.

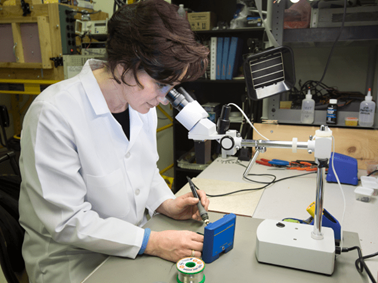

Element teams provide expert failure analysis and reporting through a range of technical services, 包括应力分析和材料表征, 痕量证据分析, 法医工程, and more.

我们提供故障分析服务的主要好处

- 通过我们精确的根本原因识别,深入了解故障我们的初步调查包括深入的发现阶段, 考虑环境因素导致失败, 申请类型, 它服役多久了, 设计特点. Element's analysts apply diverse methods and tools for detailed inspection leading to root case determination.

- 攻克复杂的非金属材料挑战非金属材料失效分析提出了一个独特的挑战. 而最初的分析过程是相同的, 我们的实验室使用专业的断口学解释和分析测试, 为这些类型的材料量身定制. As there are so many different formulations and combinations of non-metallic materials, we often use intensive material identification programs to help pinpoint the origin and degradation of non-metals.

- 确保安全和合规性我们知道可靠性和安全性在你们这个im体育平台app下载是至关重要的. Our failure analysis experts combine extensive global and national standards knowledge with years of experience, 因此,您可以对其解决方案的准确性和遵从性感到自信, 无论你身处哪个im体育平台app下载.

- Mitigate risks and navigate litigation challenges with our 专家证人服务:我们广泛的 专家证人服务 deliver critical testimony or expertise in legal and insurance cases involving material, product, 或者部件故障. 无论是合规案例, 专利侵权, 或发现滥用或缺陷的证据, 我们提供全面的支持.

- 先进有限元分析(FEA)的数字化解决方案我们的有限元分析专家使用计算机辅助设计(CAD), 在职数据, 并对材料数据进行深入分析, efficiently examining multiple failure scenarios without full-scale testing expenses. We collaborate with physical testing experts to suggest solutions and validate simulations with physical testing.

- 石油专家 & Gas Industry:为了石油 & Gas sector, 我们的专家专门分析管道, 钻井设备, pumps, valves, and seals. 我们承认关键资产失效的严重性, 提供详细的见解, 建议, 以及潜在的诉讼支持.

故障分析专家

“每次我们都需要一个故障分析和快速周转, Element has been there to fill that role with impeccable quality and turnaround time. ”

Ryan Camiré

利奇国际公司

快速、可靠、全面的故障预防解决方案

基于失效分析过程的发现, Element’s experts provide 建议 and work closely with you to find solutions for a wide range of products and materials. Our combination of materials expertise and understanding of environmental impacts means we can swiftly deliver comprehensive results, 确保解决方案和防止未来的服务故障. 您可以信赖我们提供的确定性、速度和灵活性.

Multidisciplinary Failure Analysis Approach Across the Whole Product Life Cycle

Our approach to root cause analysis of failures stretches across your whole product life cycle, from the design and selection of materials through the manufacturing process and how the product is used in service. Since issues during any one (or combination) of these stages can cause failures, 我们知道彻底调查他们是很重要的.

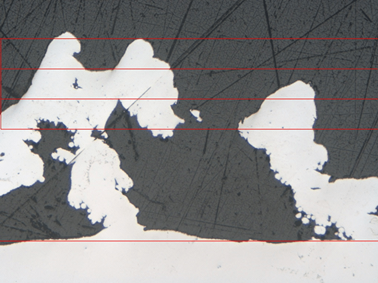

Such a broad variety of circumstances requires an equally wide range of analysis methods; that’s why we offer services ranging from fractography, 成分测定, 力学性能测试, 微观结构分析, 与材料的规格和期望比较. 洞察设计的影响, processing, 组件使用, 以及未来的行为, rest assured that we can help identify and troubleshoot your product’s failure, 无论何时发生.

您可以信赖的专家故障分析服务

腐蚀分析:

断裂分析/断口分析:

化学分析:

残留分析:

现场故障分析:

金属失效分析/冶金失效分析

附加服务:

- 故障分析调查

- 冶金咨询和专家见证

- 非金属失效分析

- 裂缝分析

- 扫描电子显微镜(SEM)

- 能量色散光谱(EDS)

- 光学显微镜

- 光学立体显微镜

- 硬度测试

- 金相制备

- 显微硬度测试

- 夹杂物分析

- 拉伸试验

- 原告-被告联合调查诉讼

- 焊缝失效分析

- 印刷电路板(PCB)故障分析

- 疲劳失效

为什么选择im体育APP?

Element在美国的实验室, UK, Europe, Middle East, 在进行故障分析方面有几十年的实践经验. Our global network of experts is recognized as some of the most trusted in their field for providing reliable failure analysis to diverse clients across many industries, including Aerospace, Energy, 运输, Construction, 医疗设备和消费产品.

我们的测试符合当地制定的一系列标准, national, and global regulatory bodies so you can be confident that 建议 from Element will be compliant. We collaborate with organizations like the American Society for Testing and Materials (ASTM), 国际标准化组织(ISO), 美国食品和药物管理局, 还有很多其他的, 确保严格监管您的材料和产品.

要了解更多关于Element的信息,请访问我们的 About Us page. 为了讨论我们如何支持您的故障分析需求, 今天就联系专家.

失效分析测试的重要性

A guide to understanding how engineering failure analysis is used to prevent failures and improve your product’s design, materials, 制造技术, 检查方法.

LEARN MORE机械故障分析

当我们收到故障分析的初始RFQ时, we have basic questions that will help us determine how complex the story is. To learn more about mechanical failure analysis, or if you have any questions, 今天就im体育APP的团队. LEARN MORE进行故障分析的三个原因

失效分析 is a process by which a failed product is inspected to determine what caused it to fail. 方法各不相同, but all seek to determine the root cause of the failure by looking at the characteristics and clues left behind.

LEARN MOREOur Services

Our teams provide expert failure analysis and reporting through a range of technical services, 包括应力分析和材料表征, 痕量证据分析和法医工程.

油的根本原因分析 & Gas Industry

Element’s failure analysis experts help you understand the causes of asset failure, 就补救行动提供意见, 并在你可能面临的任何诉讼中支持你.

聚合物失效分析

元件专家在这里帮助您对塑料进行失效分析, composites, rubbers, adhesives, sealants, 油漆和涂料.

电子设备失效分析 & Components

了解电子设备故障的根本原因,更好的构建, more reliable components with electronic device failure analysis from Element.

电池故障分析

找出电池故障的根本原因,并建立更好的, safer products with data from Element’s comprehensive battery failure analysis.

印刷电路板(PCB)故障分析

Understand and rectify the root causes of PCB failure with industry-leading PCB failure analysis from the testing experts at Element.

铁路故障分析

Element's dedicated rail testing experts work with you through every step of the process, 帮助您在进一步的损害发生之前了解缺陷和失败.

有限元分析服务(FEA)

Element offers advanced numerical analysis service using Finite Element Analysis (FEA) techniques using industry standard software to predict the long term behavior of materials components and products when in service.

专家证人服务

Element offers 专家证人服务 to legal and insurance firms to provide testimony with precision and expertise.

金相服务

我们的断口分析服务可以帮助确定故障的原因, fatigue, 或金属材料的缺陷.